Heavy-Duty Tool Sets for Professionals: Built to Handle Tough Jobs

Explore the benefits of heavy-duty tool sets built for tough jobs. From wrenches to power tools, these durable collections provide strength and reliability, helping both professionals and DIY enthusiasts handle demanding tasks with confidence and efficiency every time.

What Makes a Tool Set Truly Heavy-Duty?

Heavy-duty tool sets are distinguished by several key characteristics that separate them from standard consumer options. First, material quality stands out—professional-grade sets typically feature drop-forged steel with chrome vanadium or molybdenum alloy additions for enhanced strength. Additionally, manufacturing processes make a difference, with heat treatment, precision machining, and specialized coatings increasing longevity. Finally, design elements like reinforced stress points, ergonomic grips that reduce hand fatigue, and specialized features for specific trades all contribute to a tool set’s heavy-duty classification. These sets often carry higher torque ratings and stress tolerances than their consumer counterparts, ensuring they can handle the demands of industrial applications.

Essential Components of Durable Tool Sets for Professionals

Durable professional tool sets typically include several core components. At the foundation are ratchets and socket sets with high tooth counts (72-120 teeth) for greater precision in tight spaces, often featuring quick-release mechanisms and knurled surfaces for better grip. Heavy-duty wrenches—combination, adjustable, pipe, and torque—represent another crucial category, with the best examples providing precise tolerances and reinforced bodies. Quality screwdriver sets with hardened tips, impact-resistant handles, and magnetic properties complete most basic kits. For specialized trades, additional items like precision pliers, wire cutters, electrician’s tools with proper insulation ratings, and carpentry tools with reinforced handles become essential inclusions. The most comprehensive sets also feature storage solutions designed for job site conditions—weatherproof cases with custom foam inserts and organizational systems.

Maximizing Tool Longevity Through Proper Selection and Care

Even the most heavy-duty tool sets require proper selection and maintenance to achieve maximum longevity. When choosing tools, professionals should match specifications to their specific applications—considering factors like required torque ranges, environmental exposures (moisture, chemicals, extreme temperatures), and frequency of use. Once purchased, implementing a regular maintenance routine becomes crucial. This includes cleaning tools after each use to remove debris, applying appropriate lubricants to moving parts, storing tools in protective cases away from moisture and temperature extremes, and conducting periodic inspections for wear, damage, or loosening components. Additionally, respecting tool limitations by avoiding improvised uses (like using screwdrivers as chisels) and addressing minor issues before they worsen significantly extends service life.

Heavy-Duty Tool Sets for Mobile Professionals

For professionals who move between job sites, portability becomes as important as durability. Mobile-friendly heavy-duty tool sets address this need through thoughtful design features. Modular systems allow professionals to select only the tools needed for specific jobs, reducing weight and bulk. Consolidated kits combine multiple functions into fewer tools, while stackable storage systems with interlocking mechanisms enable efficient transport of various components simultaneously. Advanced mobile tool storage solutions feature heavy-duty wheels designed for construction site terrain, telescoping handles, weather-resistant construction, and integrated organization systems that prevent tools from shifting during transport. Some manufacturers now also incorporate tracking technology, allowing professionals to locate misplaced tools through smartphone integration.

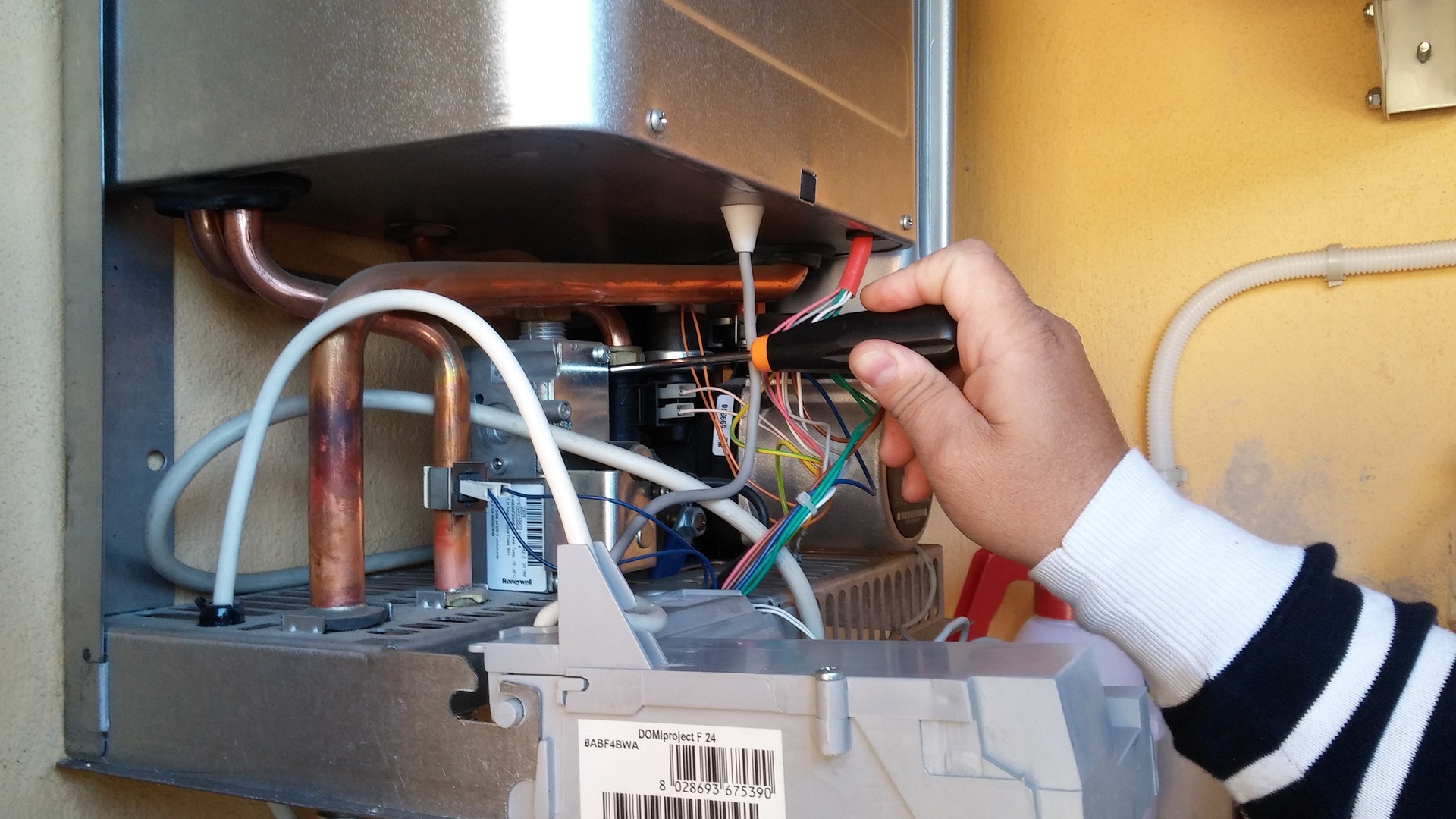

Specialized Heavy-Duty Tools for Specific Industries

Different industries require specialized heavy-duty tools designed for their unique challenges. Construction professionals need demolition tools with vibration-dampening features, automotive technicians require precision impact tools with extended reach capabilities, and manufacturing settings demand torque-specific tools with calibration capabilities. For electrical work, properly insulated tools with voltage ratings appropriate for the environment become essential safety equipment. Meanwhile, plumbers benefit from specialized pipe tools with extended handles for increased leverage in tight spaces, and HVAC technicians require refrigerant-handling tools built to withstand pressure variations and temperature extremes. Understanding these industry-specific needs helps professionals assemble appropriate heavy-duty tool collections.

Comparing Professional-Grade Heavy-Duty Tool Sets

When investing in professional-grade tools, understanding the differences between leading manufacturers helps make informed decisions. Here’s a comparison of notable heavy-duty tool set options:

| Brand | Professional Series | Key Features | Warranty | Approximate Price Range |

|---|---|---|---|---|

| Milwaukee | Packout System | Modular storage, brushless technology, ONE-KEY tracking | Limited lifetime on hand tools, 5-year on power tools | $300-$2,500 |

| DeWalt | ToughSystem | IP65 rated cases, reinforced handles, precision machined sockets | Limited lifetime warranty on mechanics tools | $250-$2,000 |

| Snap-on | Industrial Series | Flank Drive Plus wrenches, dual 80-tooth ratchets, heritage quality | Limited lifetime replacement warranty | $1,000-$15,000 |

| Ridgid | Pro Series | Full-lifetime warranty including parts/service, corrosion resistant | Limited lifetime warranty with registration | $200-$1,500 |

| Klein Tools | Journeyman Series | Trade-specific sets, dual-material handles, American-made | Limited lifetime warranty on manufacturing defects | $200-$1,200 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Evaluating Value Beyond Initial Purchase Price

When evaluating heavy-duty tool investments, professionals should consider factors beyond initial cost. Total cost of ownership includes potential replacement costs for lower-quality options, productivity impacts from tool failures or inadequate performance, and long-term durability differences. Additionally, warranty terms vary significantly between manufacturers—some offering lifetime replacements while others provide limited coverage. Service network availability becomes crucial for professionals who cannot afford extended downtime waiting for repairs or replacements. Finally, specialized features like integrated tool tracking, customization options, and proprietary technologies may justify premium pricing for professionals whose efficiency directly impacts earning potential.