How Much Do Electronic Boards Cost? A Complete PCB Pricing Guide

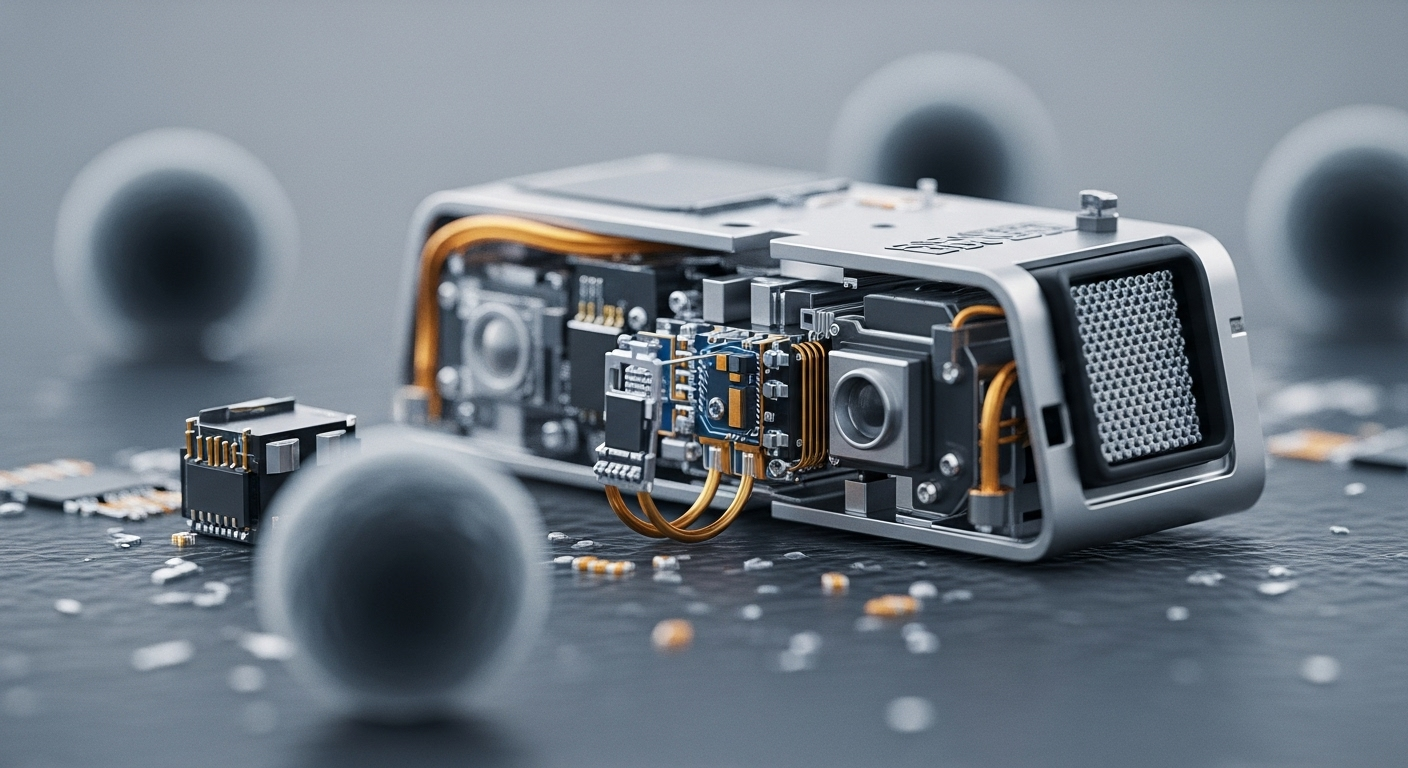

Printed circuit boards (PCBs), also known as printed wiring boards (PWBs), are essential to modern electronics. Whether you're building devices or replacing parts, the cost of electronic boards can vary widely. Find out current pricing and what affects it today.

What Determines Electronic Board Pricing?

The cost of electronic boards varies significantly based on several key factors. Board size, layer count, and material quality are primary cost determinants. Simple single-layer boards might cost a few dollars, while complex multilayer boards for specialized applications can reach hundreds or thousands of dollars. Manufacturing quantity also plays a crucial role, with per-unit costs decreasing significantly for larger orders.

Basic PCB Cost Components

Material costs typically account for 30-40% of the total PCB price. This includes the substrate material, copper foil, solder mask, and silkscreen. Labor costs contribute another significant portion, particularly for complex designs requiring precise manufacturing processes. Additional features like special coatings, higher copper weight, or specific testing requirements can further increase the price.

Current Market Pricing Overview

Electronic board pricing varies widely based on specifications and quantity. Here’s a detailed breakdown of current market rates:

| Board Type | Quantity | Estimated Cost (USD) |

|---|---|---|

| Single Layer | 1-10 pcs | $5-15 per board |

| Double Layer | 1-10 pcs | $20-40 per board |

| 4-Layer | 1-10 pcs | $40-100 per board |

| 6-Layer | 1-10 pcs | $80-200 per board |

| 8+ Layer | 1-10 pcs | $150-500+ per board |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Common Price Variables in Electronic Board Manufacturing

Several factors can significantly impact the final cost of electronic boards:

-

Board dimensions

-

Material selection

-

Layer count

-

Minimum trace width

-

Hole size and count

-

Surface finish type

-

Production volume

-

Turnaround time

-

Testing requirements

Cost-Saving Strategies for PCB Production

To optimize electronic board costs without compromising quality, consider these approaches:

-

Order in larger quantities when possible

-

Standardize design specifications

-

Use common materials and components

-

Plan for panel utilization

-

Choose appropriate surface finishes

-

Consider domestic vs. overseas manufacturing carefully

-

Bundle orders with other projects

The electronic board market continues to evolve with technological advances and changing manufacturing capabilities. While basic boards remain relatively affordable, specialized designs can command premium prices. Understanding these cost factors helps in budgeting effectively for electronic board projects and making informed decisions about specifications and quantities.