Precision Machining Advancements in Canadian Industry

CNC metal cutting is widely used to produce complex parts with accuracy and efficiency. Exploring its applications provides insight into how modern manufacturing relies on technology for consistency and quality, without implying fixed performance or cost advantages.

How CNC Metal Cutting Supports Modern Canadian Manufacturing

Computer Numerical Control (CNC) metal cutting plays a pivotal role in supporting various facets of modern Canadian manufacturing. This technology enables the precise fabrication of intricate parts with high accuracy and consistency, which is crucial for industries requiring tight tolerances. From aerospace components to medical devices and automotive parts, CNC machines can process a wide array of materials, including steel, aluminum, titanium, and various alloys.

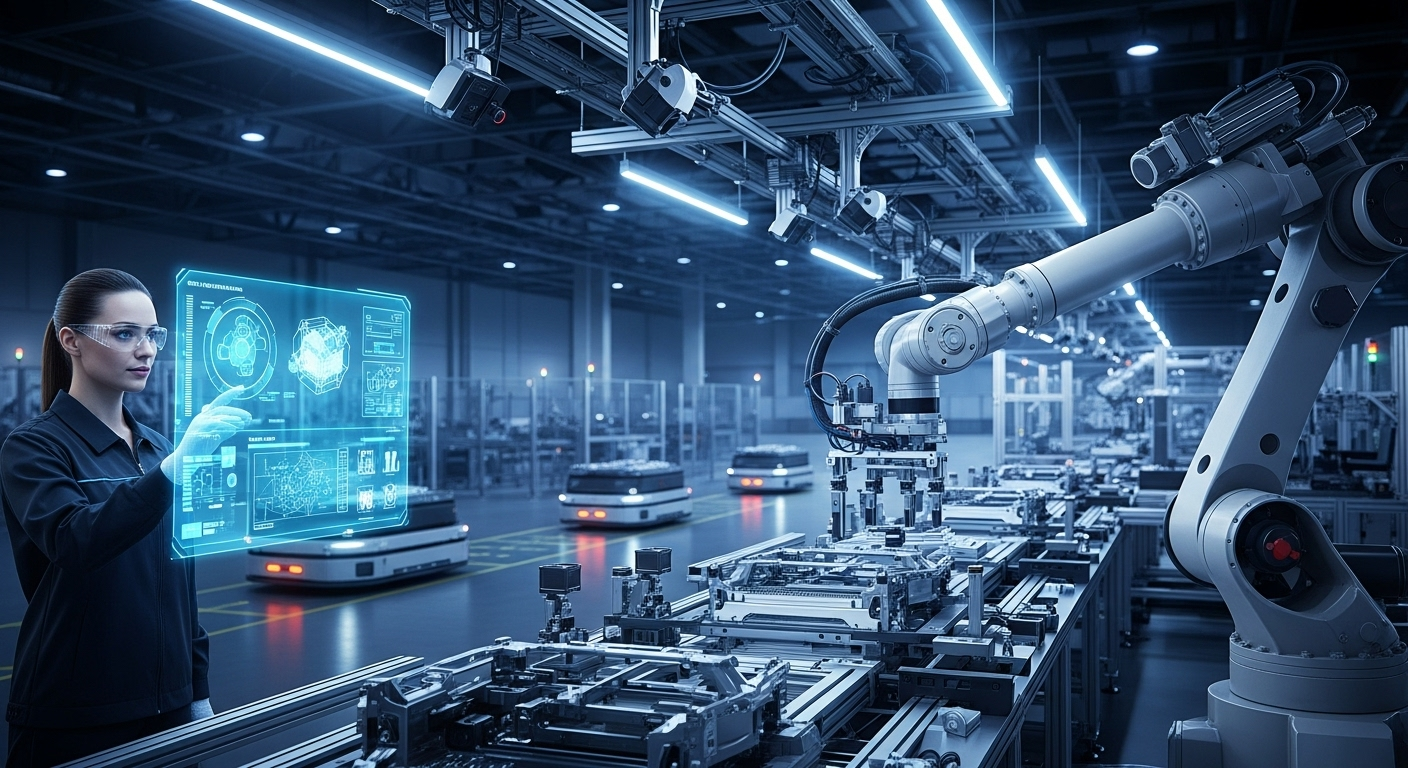

By automating the cutting process, CNC systems minimize human error and significantly increase production speed compared to traditional methods. This efficiency allows Canadian manufacturers to meet demanding production schedules and maintain high quality standards, contributing to their competitiveness in both local and global markets. The ability to produce complex geometries and reproduce them consistently is a key advantage, fostering innovation in product design and functionality across the country.

Understanding CNC Metal Cutting Processes in Manufacturing

CNC metal cutting refers to a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. It encompasses several methods, each suited for different materials and desired outcomes. Common CNC cutting techniques include milling, turning, laser cutting, plasma cutting, and waterjet cutting.

CNC milling involves rotating multi-point cutting tools that remove material to shape a workpiece, while CNC turning uses a single-point cutting tool to remove material from a rotating workpiece. Laser cutting employs a focused laser beam to melt, burn, or vaporize material, offering high precision for thin materials. Plasma cutting uses an accelerated jet of hot plasma for thicker conductive materials, and waterjet cutting uses a high-pressure jet of water, often mixed with an abrasive, for a wide range of materials without heat distortion. Each process offers distinct advantages, allowing manufacturers to select the most appropriate method for their specific application and material requirements.

How CNC Metal Cutting Improves Manufacturing Practices

The integration of CNC metal cutting significantly improves manufacturing practices by enhancing efficiency, reducing waste, and improving workplace safety. The automated nature of CNC machines leads to more consistent product quality and fewer defective parts, which in turn reduces material waste and rework costs. This level of precision is vital for industries where component failure can have significant consequences.

Furthermore, CNC technology allows for faster prototyping and shorter lead times, enabling Canadian businesses to respond more quickly to market demands and adapt product designs with greater agility. By automating repetitive and potentially hazardous tasks, CNC machines also contribute to a safer working environment for employees. The scalability of CNC operations means that production can be easily adjusted from small batches to large volumes, providing flexibility that is essential for modern supply chains and supporting local manufacturing capabilities.

| Service Type | Typical Applications | General Cost Factors |

|---|---|---|

| CNC Milling Services | Prototypes, complex parts, molds, fixtures | Machine time, material cost, part complexity, setup time, quantity |

| CNC Turning Services | Shafts, cylindrical parts, fittings, bushings | Machine time, material cost, part complexity, setup time, quantity |

| Laser Cutting Services | Sheet metal parts, intricate designs, engraving | Material type and thickness, cut length, machine power, quantity |

| Plasma Cutting Services | Thick metal plates, structural components | Material type and thickness, cut length, machine time, quantity |

| Waterjet Cutting Services | Heat-sensitive materials, thick materials, composites | Material type and thickness, cut length, abrasive cost, machine time, quantity |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Investing in Canadian Manufacturing Capabilities

Investing in advanced manufacturing capabilities, particularly through CNC metal cutting technologies, positions Canadian industries for future growth and innovation. These advancements enable companies to produce high-quality, complex components efficiently, supporting various critical sectors. The continuous adoption of such precision machining techniques helps maintain a competitive edge, fostering economic development and strengthening the nation’s industrial base. As technology evolves, further enhancements in automation and digital integration are expected to drive even greater efficiencies and open new possibilities for manufacturing in Canada.